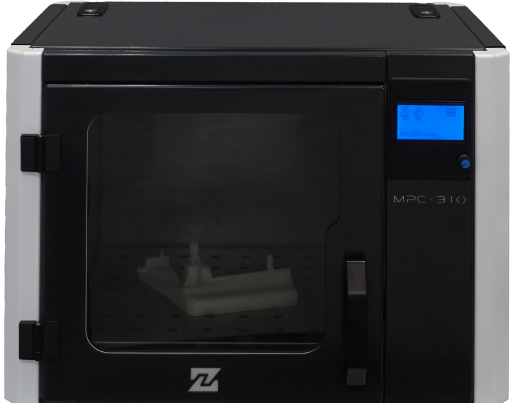

Buy post processing center Total Z MPC‑310

Acetone baths implement the chemical method of post‑processing of products.

The machines help to achieve a glossy and smooth 3D print’s surface.

The machines help to achieve a glossy and smooth 3D print’s surface.

Features

Automatic collecting and cleaning of a reagent

Uniform heating for a quick drying

Forced circulation of a reagent

Processing models from ABS, ABS+, PLA, ASA

Different types of reagents

Touch screen controls

Development of the first acetone vapor baths, or post processing machines, began in 2020,

related to the internal needs of making smooth and glossy prints for the clients.

The first post‑processing machines were made in 2021, which marked the beginning of the serial production of this type of equipment.

The first post‑processing machines were made in 2021, which marked the beginning of the serial production of this type of equipment.

Specification

KEY CHARACTERISTICS

Volume (XYZ, mm)

310×310×310

Inner space material

stainless steel AISI 304, 2 mm

PHYSICAL CHARACTERISTICS

Outer dimensions

560×380×420 mm

Weight

48 kg

POWER SUPPLY

Requirements

220V, single phase

Max. power consumption

1.4 kWt, 7A

REAGENTS

acetone, dichloromethane

Other post processing solutions

Ultrasonic bath

Ultrasonic bath implements the physicochemical method of post‑processing.

This equipment helps to remove soluble supports, made from HIPS and PVA, from the surface of 3D prints including hard‑to‑reach places.

This equipment helps to remove soluble supports, made from HIPS and PVA, from the surface of 3D prints including hard‑to‑reach places.

Vacuum filament dryer

The vacuum drying chamber allows to dry 4 spools up to 2,5 kg simultaneously.

Maximum temperature — 150°С. Perfect for drying high‑temperature plastics — Ultem 9085/1010, PEI, PEEK, PEKK, PSU, etc.

Maximum temperature — 150°С. Perfect for drying high‑temperature plastics — Ultem 9085/1010, PEI, PEEK, PEKK, PSU, etc.