Buy ultrasonic bath

Ultrasonic bath implements the physicochemical method of post‑processing.

This equipment helps to remove soluble supports, made from HIPS and PVA, from the surface of 3D prints including hard‑to‑reach places.

This equipment helps to remove soluble supports, made from HIPS and PVA, from the surface of 3D prints including hard‑to‑reach places.

Features

Customization of equipment according to client’s requirements

Stainless steel case

Maximum volume more than 1 cubic meter

Cleaning any size and geometry items

Cleaning with water, alcohol or D‑limonene

Touchscreen control panel

The design of the ultrasonic bath is carried out in accordance with the client’s technical specifications.

Standard sizes:

— 700×550×500 mm,

— 1230×680×1230 mm.

Standard sizes:

— 700×550×500 mm,

— 1230×680×1230 mm.

Specification

KEY CHARACTERISTICS

Inner dimensions

700×550×500 or 1230×680×1230 mm (depends on requirements)

Inner volume material

stainless steel AISI 316L

Case material

stainless steel AISI 304

Emitting surface

bottom

Ultrasonic frequency

25 ± 5% kHz

Ultrasound power

up to 3 kW or up to 7.5 kW (depends on requirements)

Programmed timer

from 1 minute to 10 hours

Temperature control

from ambient to 80 С°

Heating element power

up to 3 kW or up to 7.5 kW (depends on requirements)

Type of installation

floor

Control interface

touch panel

POWER

Supply voltage

380V, 50Hz

Bath power consumption

up to 15 kW (up to 30 kW, depending on the requirements)

Connection to the water supply network, R

up to 4.0 kgf / cm²

Compressed air consumption, R

up to 5.0 kgf / cm² (flow rate from 160 l / min)

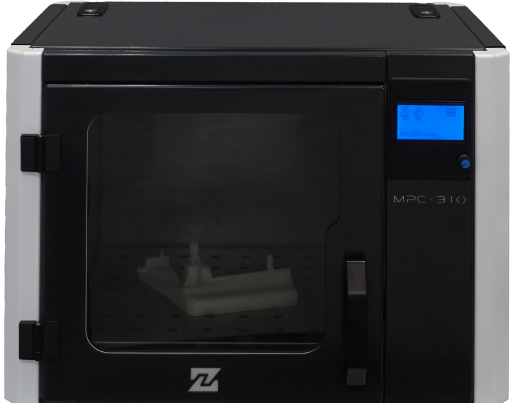

Other post processing solutions

Vapor baths

Acetone baths implement the chemical method of post‑processing of products.

The machines help to achieve a glossy and smooth 3D print’s surface.

Vacuum filament dryer

The vacuum drying chamber allows to dry 4 spools up to 2,5 kg simultaneously.

Maximum temperature — 150°С. Perfect for drying high‑temperature plastics — Ultem 9085/1010, PEI, PEEK, PEKK, PSU, etc.

Maximum temperature — 150°С. Perfect for drying high‑temperature plastics — Ultem 9085/1010, PEI, PEEK, PEKK, PSU, etc.